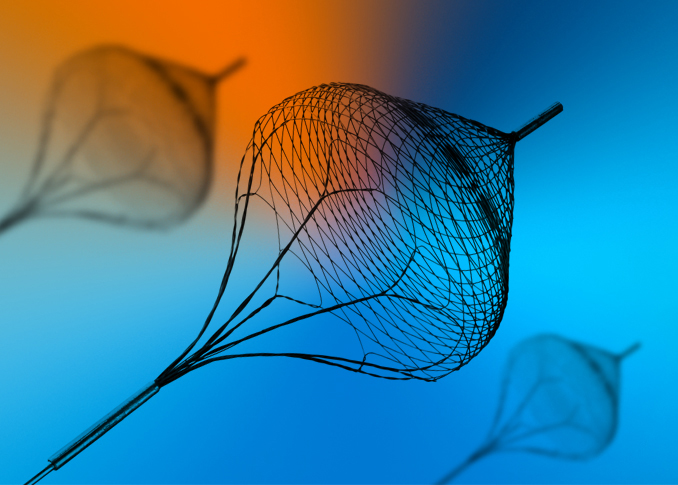

Nitinol Components

Request a Quote »

Automated Nitinol Braiding

Precision, Scalability, and Engineering Support

Whether you need rapid prototypes or full-scale production, Nordson MEDICAL delivers with our first-of-its-kind automated braiding platform. We combine advanced automation with deep expertise in complex nitinol wire braiding and forming—backed by millions of nitinol components deployed in the field today. With precise control over braid geometry and full lifecycle support, we help engineers reduce development time and cost while ensuring performance and manufacturability.

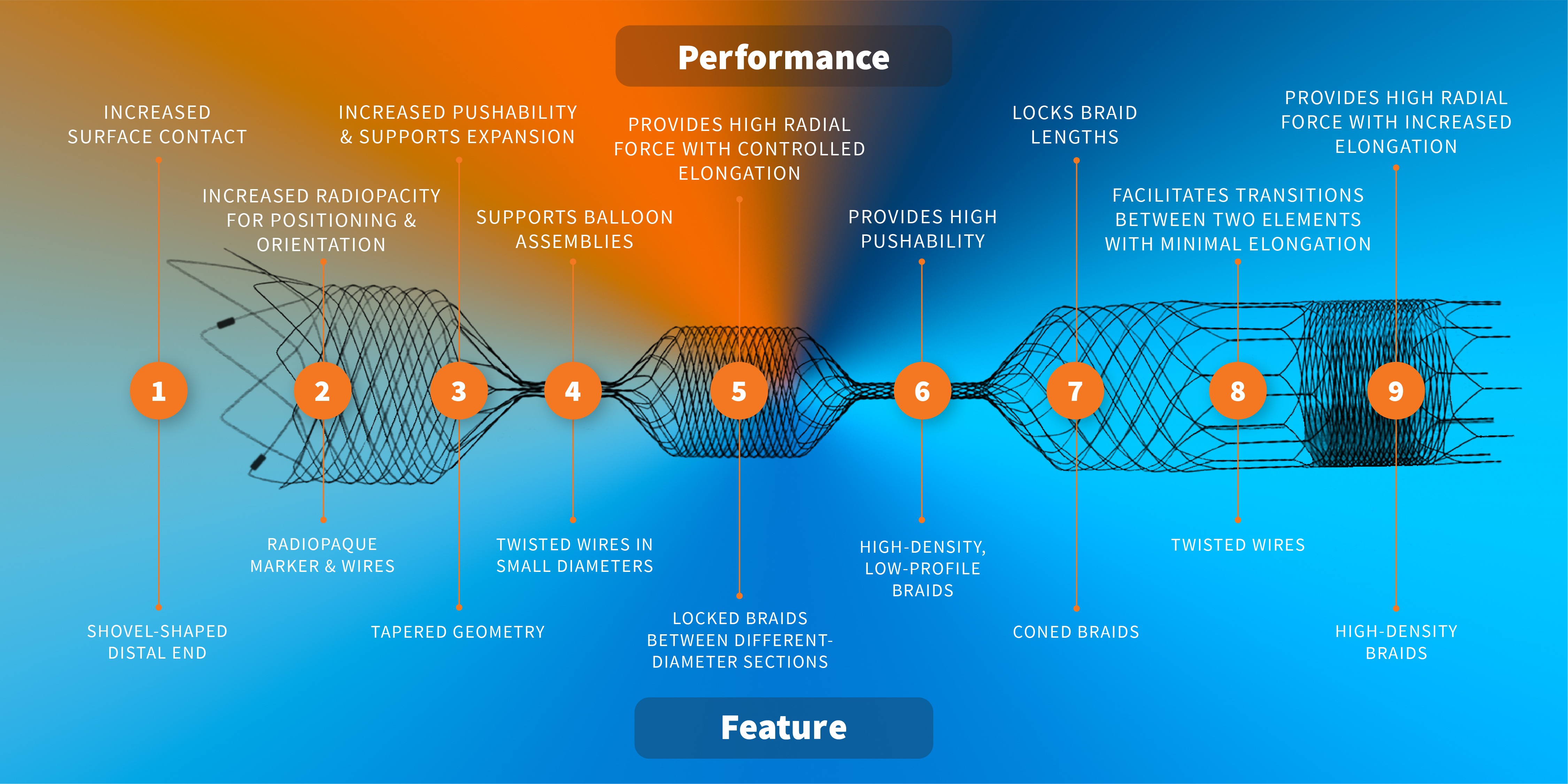

Request a Quote »Engineering Advantages of Complex Nitinol Structures