Polyimide Tubing

Request a Quote »

Polyimide and Composite Film Cast Tubing

Upgrade Your Devices

Nordson MEDICAL has the broadest, most versatile medical tubing line in the industry. Our extensive selection of polyimide tubing features:

- Very thin wall thickness

- Tight-tolerance inner and outer diameters

- Outstanding electrical insulation properties

- Stiffness and column strength as required

- Ability to withstand very high temperatures

- 81 different layering and custom composite configurations

Applications of Polyimide

With a multitude of various configurations available, our polyimide tubing is used in a wide range of applications:

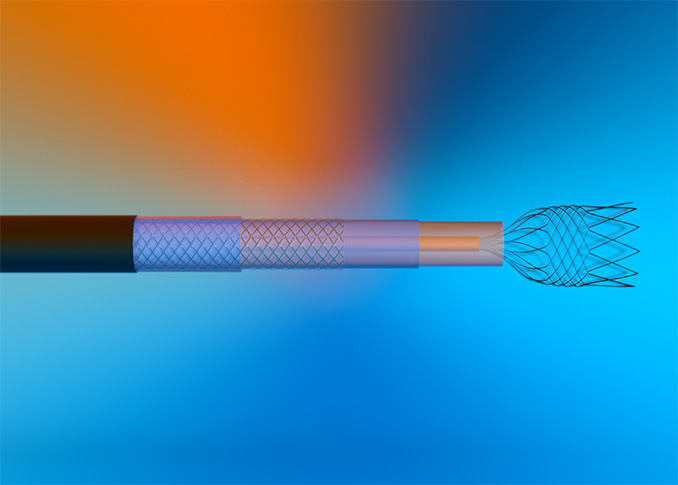

- Retention sheath for self-expanding stents

- Inflation lumen for balloons

- Suction lumen for atherectomy devices

- Liner material for lumens containing catheter-steering wires

- Low-diameter guidewire designs or guidewire outer sheaths

- High-temperature or gamma radiation-resistant tubing applications

- Applications requiring high tensile strength, torque transmission, or column stiffness

- Precision wire coating

Configurations

Polyimide to Fit Your Needs

We offer a full range of thin-wall polyimide tubing products. Our made-to-order, tight-tolerance polyimide tubing is manufactured to your specifications. Contact us to discuss your needs.

- More than 200 configurations of tight-tolerance polyimide tubing

- Inner diameter (ID) range: 0.004"–0.085" (in 0.001" increments)

- Wall thicknesses: thick, thin, and ultrathin (0.0005"–0.0100")

- Colors: amber, red, yellow, black, and green

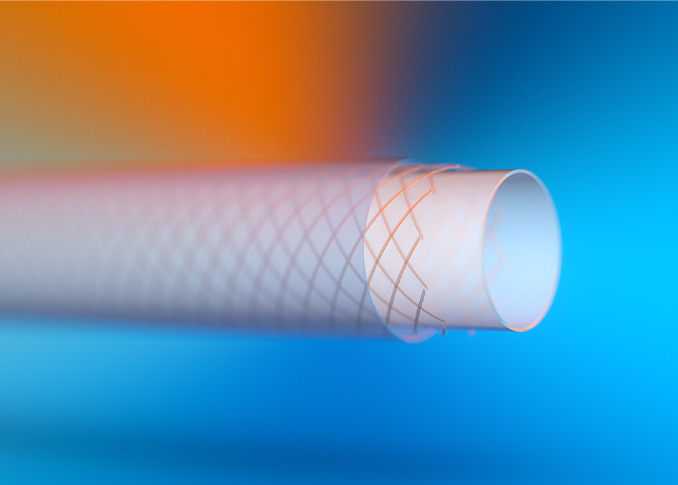

Composite Tubing

Meeting Your Performance Characteristics Requirements

Thin-wall polyimide tubing can be blended, braided, or layered with multiple polymers to get the performance characteristics your application requires:

- Low-friction layer inside or outside

- Fusible thermoplastic outer layer

- Improved kink radius

- Excellent torque when braided

Our composite tubing features:

- More than 80 layer combinations

- Many materials, including PTFE, Nylon, Pebax®, Polyurethane, Polyphenylsulfone, and Polyimide

Precision Wire Coatings

For Your Application

Because of its outstanding electrical insulation properties, polyimide makes an ideal wire coating, with:

- High dielectric strength

- Precision tolerances

- Resistance to chemicals and high temperatures

- Thin wall thickness

- High strength

Braid-Reinforced Tubing

Our braid-reinforced tubing comprises 4+ layers with wire braid in the middle for torque, tensile strength, and kink resistance. Why choose polyimide over extrusions?

- Smaller diameters

- Thinner wall thickness

- Tighter tolerances

We carry a variety of configurations of braid-reinforced tubing.

- ID range: 0.013"–0.074"

- Wall thickness range: 0.002"–0.008"

Our made-to-order braid-reinforced tubing is manufactured to your specifications:

- ID range: 0.004"–0.420"

- Wall thickness range: 0.0005"–0.010"

Technical Information

Technical Information

| ID Range | 0.004"–0.085" (0.102 mm–2.159 mm) |

| Wall Thickness Range | 0.0005"–0.0100" (0.0127 mm–0.2540 mm) |

| OD Tolerance | ±0.0002"–±0.0005" (±0.0051 mm–±0.0127 mm) |

| Length | Standard: 36"–55"

Maximum: 32' Custom Cutting: 0.020"–73.0"

|

| Color | Amber (transparent)

Can be produced in a variety of colors including black, green, yellow, red, and others |

| Printing | Can be printed using conventional techniques |

Technical Information

| Polymer Type | Thermoset |

| Tensile Strength | 20,000 psi (minimum) |

| Elongation (at Break) | 30% min |

| Modulus of Elasticity | 310 kpsi |

| Dielectric Strength | 4000 V/.001" |

| Moisture Absorption | 0.841 wt% (24 hours) |

| Melting Temperature | n/a |

| Thermal Range | -269°C–400°C (-452°F–752°F) |

| Thermal Conductivity | 0.471 W/m*K |

| Coefficient of Friction | 0.5 (dry, dynamic) |

*Example material properties. Actual material properties may vary depending on specifications.

- USP Class VI compliant

- Chemically inert

- Excellent chemical resistance

- Excellent torque transmission

- Excellent column strength

- Nonmelting

- Microsize IDs

- Transparent