Ram-Extruded Tubing

Request a Quote »

Ram-Extruded PTFE Tubing

World-Leading Manufacturer

Choose Nordson MEDICAL, and choose one of the world's leading manufacturers of custom ram-extruded PTFE tubing for the medical industry. Ram-extruded PTFE tubing is an ideal material choice for medical device applications that require maximum surface lubricity, high chemical and thermal resistance, and/or exact extrusion tolerances.

Inquire Today »

Capabilities

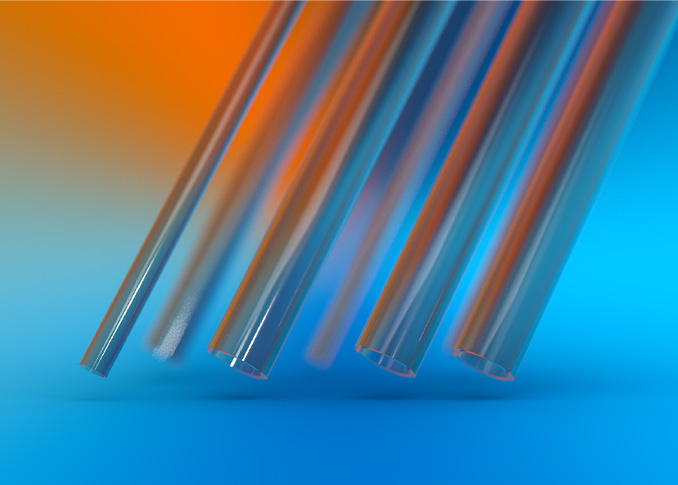

Ram-Extruded PTFE Liner Tubing

We offer a wide range of chemically inert PTFE tubing that delivers excellent dielectric insulation properties, a working temperature range of 500°F to -400°F, and high thermal resistance.

Our custom ram-extruded PTFE capabilities include:

- Custom profiles and monofilament

- Custom multi-lumen: 2-6 lumens

- Micro-bore: 0.002"-0.350" (0.051 mm - 8.89 mm) IDs

- Thin wall: walls from 0.001" (0.025 mm)

- Radiopaque fillers

- Inline and dip etching

- Tear-away/splittable sheath

- Custom colors

- Can be extruded over silver-plated, copper-core mandrels

- Slitting

Properties of PTFE

Enhancing Features

PTFE (polytetrafluoroethylene) has the lowest coefficient of friction of any polymer, making it a popular choice for catheter applications that require lubricity.

It also features:

- Temperature and chemical resistance

- Biocompatibility

- Precise Tolerances

- High dielectric strength

- Excellent insulative properties

Contact us to discuss how a PTFE tubing could advance your next project.

Contact Us »

Film-Cast Liner

PTFE Tubing

When your catheter assembly needs a lubricious inner layer, a PTFE liner is the ideal choice. But not all PTFE liner tubing is the same.

Learn more about what sets our film-cast PTFE liner tubing apart.

Learn More »Ram-Extruded Tubing Technical Information

Technical Information

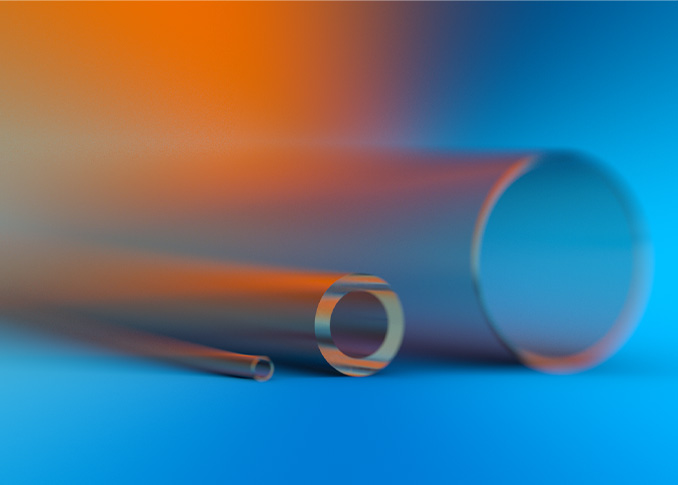

| Tubing Options | Single-lumen tubing

Multi-lumen/profile extrusions Thin-wall & micro-bore tubing Radiopaque tubing Splittable tubing Etched liners |

| Upper Service Temperature | 500°F/260°C |

| Melting Point | 635°F - 650°F/327°C |

| Tensile Strength | 2500 - 4000 psi |

| Specific Gravity | 2.13 - 2.24 |

| Coefficient of Friction | 0.08 |

| Device Components |

|

| Capabilities |

|

| Sterilization |

|

- Chemically inert

- High temperature resistance

- Outstanding dielectric properties

- Excellent surface lubricity

- Beading/custom profiles

- Multi-lumen

- Heat shrink

- Splittable

- Bismuth trioxide

- Bismuth subcarbonate

- Custom colors

- Notching/drilling

- Flaring/flanging/tipping

- Etching