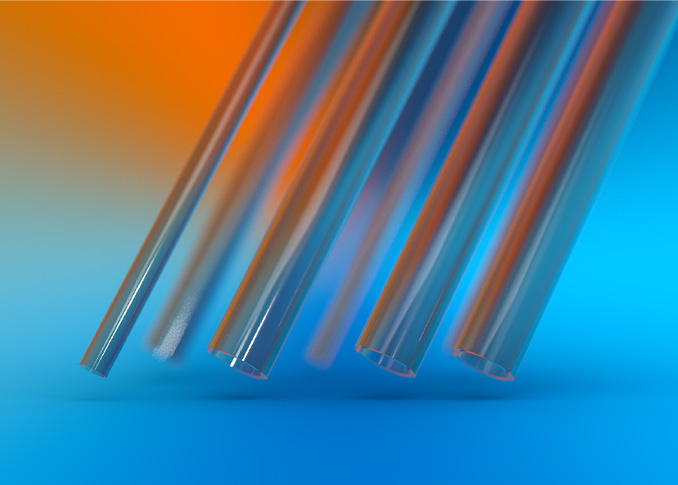

Film-Cast Liner Tubing

Request a Quote »

Film-Cast PTFE Liner Tubing

Enhance Your Medical Devices

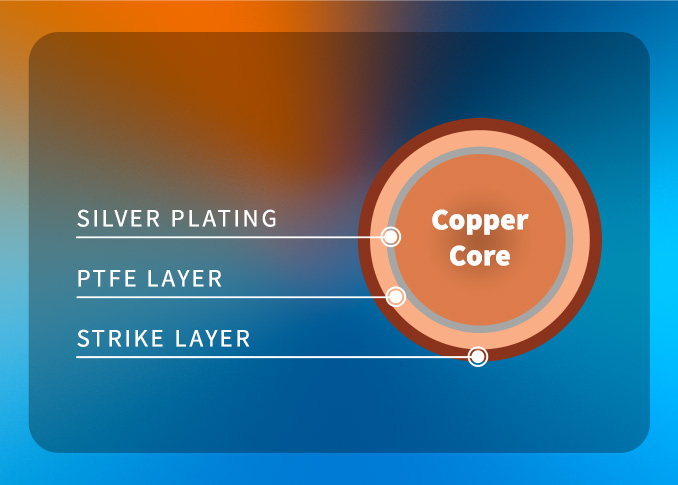

When your catheter assembly needs a lubricious inner layer, a PTFE liner is the ideal choice. But not all PTFE liner tubing is the same. We supply etched PTFE liners on solid, silver-plated copper-core mandrels, which give you the advantage of having thinner walls and time savings.

Inquire Today »

Advantages

Film-Cast PTFE Liner Tubing

What makes our PTFE liners different? We provide them on silver-plated, copper-core mandrels, so you don't have to stretch the liner onto another mandrel.

Other advantages include:

- Ultrathin walls (0.0004" - 0.002")

- Precise dimensions

- High flexibility with minimal stiffness added to the catheter shaft

- Improved adhesion with strike layer (a thin thermoplastic outer layer to enhance adhesion)

- Option of cut lengths or continuous-spooled lengths

Strike Layer

Enhancing Adhesion

Our PTFE liners on mandrels can be fabricated with a thin thermoplastic outer layer to enhance adhesion. This "strike layer" adds more bond strength between the etched PTFE surface and the catheter assembly. Strike layers are available in a wide range of thermoplastic materials, including, but not limited to:

- Nylon (11 and 12)

- Pebax® (55D, 70D, 72D, and others available)

- Polyurethane (Tecoflex®)

Contact us to discuss how a PTFE liner with strike layer could advance your next project.

Contact Us »

Ram-Extruded Tubing

Made With PTFE

Choose Nordson MEDICAL, and choose one of the world's leading manufacturers of custom ram-extruded PTFE tubing for the medical industry. Ram-extruded PTFE tubing is an ideal material choice for medical device applications that require maximum surface lubricity, high chemical and thermal resistance, and/or exact extrusion tolerances.

Learn More »Film-Cast Liner Tubing Technical Information

Technical Information

| Inner Diameter (ID) Range | 0.014"–0.096" (0.35 mm–2.4 mm) |

| Outer Diamter (OD) Range | 0.015"–0.099" (0.38 mm–2.5 mm) |

| Wall Thickness | 0.0004"–0.002" (0.010 mm–0.051 mm) |

| Length | Custom cut or continuous-spooled lengths |

PTFE (polytetrafluoroethylene) has the lowest coefficient of friction of any polymer, making it a popular choice for catheter applications that require lubricity.

It also features:

- Temperature and chemical resistance

- Biocompatibility

- Precise tolerances

- High dielectric strength

- Excellent insulative properties