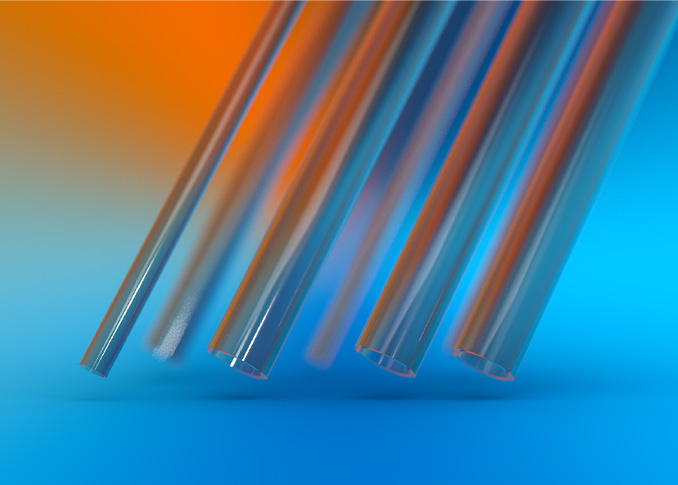

PTFE Tubing

Request a Quote »

Polytetraluoroethylene

The First Fluoropolymer

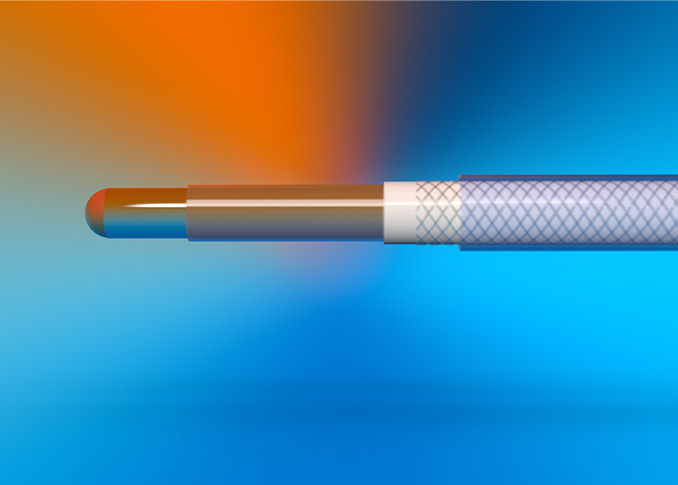

PTFE was the first fluoropolymer to be discovered. It is also the most difficult to process. Because its melt temperature is only a few degrees shy of its degradation temperature, it cannot be melt-processed. PTFE is processed using a sintering method, where the material is heated to a temperature below its melting point for an extended period of time. The PTFE crystals unravel and interlock with each other, allowing the plastic to take the shape it is intended to take. PTFE has been used in the medical industry as early as the 1960s. Today, it is typically used for split-sheath introducers and dilators, as well as lubricious catheter liners and heat shrink tubing. Because of the chemical stability and low coefficient of friction, PTFE is an ideal catheter liner.

Film-Cast Liner Tubing » Ram-Extruded Tubing »Choosing PTFE Tubing: A Comparison of Film-Cast and Ram-Extruded PTFE Tubing

Nordson MEDICAL is a pioneer and innovator in the design, development, and manufacturing of PTFE tubing. There are primarily two ways of producing PTFE tubing — the film-cast process and the ram-extrusion process. Both make great lubricious catheter liners, but each method results in a different set of characteristics. Our new whitepaper details these characteristics and explains why film-cast PTFE is ideal for thin-walled liners, and why ram-extruded PTFE is preferred for larger-bore delivery systems or for any device requiring high tensile strength and durability. Read the whitepaper to determine which type of tubing is best for your design and application.

Properties

Why PTFE?

PTFE has the lowest coefficient of friction of any polymer, making it a popular choice for catheter applications that require lubricity. It also features:

- Temperature and chemical resistance

- Biocompatibility

- Precise tolerances

- High dielectric strength

- Excellent insulative properties

Enhance Your Catheter Devices

With PTFE Liners

PTFE (polytetrafluoroethylene) provides a lubricious inner layer ideal for catheter applications that require low friction for enhanced:

- Guidewire tracking

- Fluid flow

- Passage of other devices

- Irrigation

- Steering wire tracking

- Liner

- Balloon protectors

- Introducer sheaths

- Fluid transfer tubing

Ram-Extruded Tubing

World-Leading Manufacturer

Choose Nordson MEDICAL, and choose one of the world's leading manufacturers of custom ram-extruded PTFE tubing for the medical industry. Ram-extruded PTFE tubing is an ideal material choice for medical device applications that require maximum surface lubricity, high chemical and thermal resistance, and/or exact extrusion tolerances.

Learn More »