Extruded Tubing

Shop Now »

Medical-Grade Extruded Tubing

From Simple to Complex

Nordson MEDICAL has a long, successful track record of supplying high-precision, specialized extruded tubing to the medical device industry. A global partner with facilities around the world, we specialize in high-performance tubing for critical applications. We know that speed to market is key, so we offer expertise in premium, medical-grade extruded tubing with expanded capacity in our U.S. and European facilities with less than two week lead times on new projects specific to multi-layer PTA/PTCA applications, single-lumen, and multi-lumen tubing. We also scale to your production needs with confidence through FDA registered production sites, ISO 13485 certified facilities, and Class 8 qualified production cleanrooms.

Inquire Today »

Customized Materials

Meeting Your Needs

- Full range of thermoplastics

- Full range of Fluoroplastics (FEP, PTFE)

- Engineering plastics (PEEK, Polysulfone)

- Custom compounds: colorants, stabilizers, radiopaque fillers, and active agents

Lubricious Materials & Additives

Used as Tubing Liners

Lubricious materials are used as a tubing liner, as an alternative to hydrophilic coatings, or as a way to improve bonding to other components. We have multiple configurations of lubricious, single-lumen extruded tubing available with the following market-leading lubricious additives: EverGlide®, PEBASlide, ProPell S™, and Mobilize. Contact us to discuss custom medical extruded tubing with lubricious materials and additives.

Contact Us »

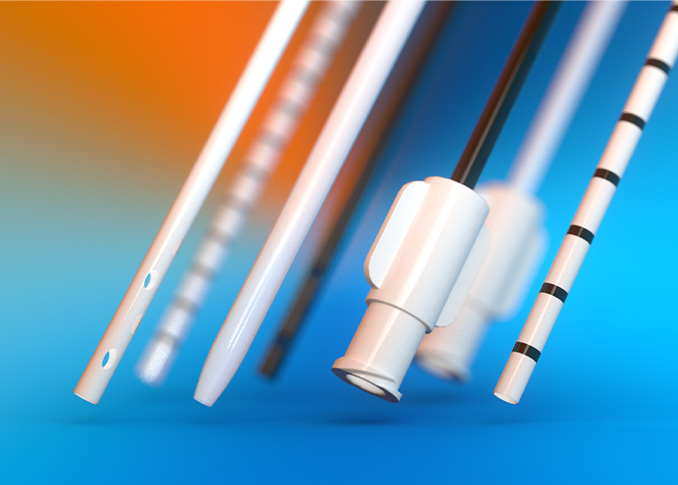

Secondary Processes

Enhancing Functionality and Versatility

Nordson MEDICAL offers a comprehensive range of secondary processes for extruded tubing, enhancing the functionality and versatility of our products while maintaining cost-efficiency through automation. These secondary processes include:

- Tipping:

Tipping involves the formation of a radius or chamfer at the end of the tube, facilitating assembly and device insertion. Nordson MEDICAL offers a variety of tipping capabilities, from closed and tapered tips to radiopaque and soft tips, ensuring compatibility with a wide range of applications. - Printing:

Printing adds branding, markings, and other essential information to medical devices and components. Nordson MEDICAL offers various printing capabilities, including text, numeric identifiers, depth marks, and surface treatments, with a range of colors available for customization. - Hole Forming:

Hole forming is crucial for creating access points to extrusion channels, serving purposes like balloon inflation and irrigation. Nordson MEDICAL can achieve virtually any hole or skive pattern, with precise cutting edges and multi-lumen configurations to meet specific device requirements. - Over-Molding:

Over-molding seamlessly combines one or more materials to create a single part, commonly used for inflation or liquid transfer connections. This process opens up endless possibilities for profile, size, and performance customization, with the potential to incorporate components like Y-connectors, hubs, and strain reliefs.

In-House Equipment & Expertise

Nordson MEDICAL brings state-of-the-art extrusion equipment together with materials and engineering expertise to develop specialized extruded tubing for the most demanding interventional and surgical applications. We offer:

- Best-in-class tolerances

- Fastest medical polyurethane line in the world (> 300 million feet annually)

- Automatic closed-loop feedback systems that allow us to maintain constant melt pressure to minimize process variation

- Validated processes to support customer compliance

- Cleanroom environment for most commercial extrusions

Our Capabilities

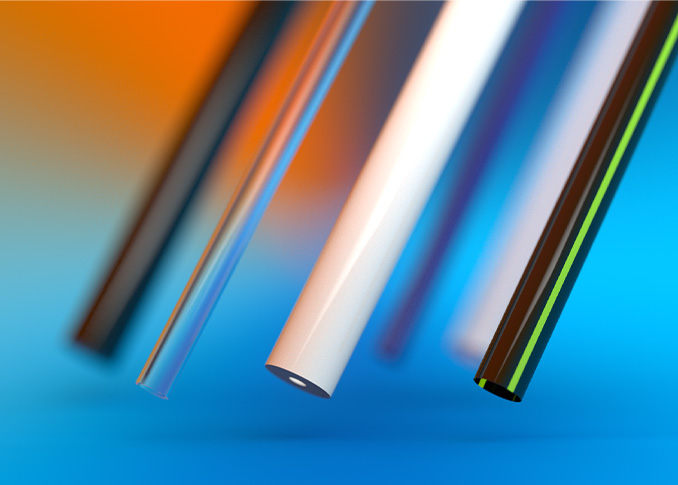

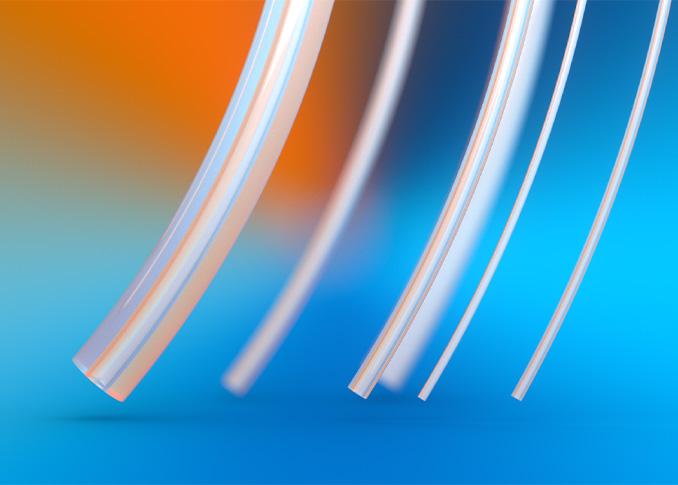

Our single-lumen tubing includes ultrathin-wall tubing and microthin-wall tubing.

From simple to the most complex designs, our multi-lumen tubing has 2-9 lumens for simultaneous passage of guidewires, catheters, fluids, and/or gasses. The number of lumens depends on the material and cross-sectional area. Lumens can be shaped to meet user requirements and contained within a round tube or other cross section like an oval or figure-eight.

The extrusion of multiple layers of material is done simultaneously to produce multi-layer tubing. Multi-layer technology is primarily used to improve functionality; for example, to combine a weldable material with one that has other performance characteristics, like lubricity. These constructions can also increase performance and possibly reduce overall assembly and material costs, making the medical device more cost effective for the customer. Other key functionalities may include active material layers, such as hydrophilic, bioresorbable, or drug-eluting layers. The technology and materials now used to produce multi-layer products for today's medical devices have advanced greatly and provide the designer with a wealth of opportunities for optimizing size, materials, and functionality.

Co-extruded multi-layer tubing can combine materials with different but complementary properties, including durometer, color, opacity, radiopacity, or tensile strength, to provide custom catheter solutions. The most common application is medical extruded tubing with radiopaque stripes visible under x-ray. This is accomplished by encapsulating stripes containing a filler visible under x-ray within the wall of the tubing. Typical fillers include these compounds, which can be used in various concentrations to enhance radiopacity:

- Barium sulphate

- Bismuth trioxide

- Bismuth subcarbonate

- Tungsten

Advanced Co-Extruded Multi-Layer Extruded Tubing Allows Smaller, Thinner, More Functional Catheter-Based Medical Devices

Advances in multi-layer medical extruded tubing have come a long way in providing increased capability to procedures that were previously difficult to execute.

Technical Information

| Co-Extruded Multi-Layer Component | Desired Primary Property on Inner Layer | Inner Layer Material | Desired Primary Property on Outer Layer | Outer Layer Material |

|---|---|---|---|---|

| PTA/PTCA Inner Tubing | Lubricity | HDPE | Bondable to adjacent device components | Nylon 12 |

| Infusion Tubing | Chemical inertness | HDPE | Flexibility | PVC |

| Tungsten-Polymer Marker Band | Radiopacity | 80% Tungsten-filled PUR | Smoothness | PUR |

| Implantable Central Venous Catheter | Flexibility | PUR | Antimicrobial | Silver ion-filled PUR |

| Coronary Implant Delivery System | Lubricity | HDPE | Bondable to adjacent device components | Pebax |

Tapered tubing has a transition in outer and inner diameter in a section of the extruded tube. More complex than typical extrusion operations, tapered tubing production requires sophisticated control on the tube pulling/cutting station combined with other process equipment to achieve precise tapered tubing dimensions.

Bump tubing is similar to tapered tubing but has a bump (area of increased outer diameter) along the length of the tube.

The dimensions that can be achieved using this technology depend on the material used. Advantages of this type of specialized extruded tubing include eliminating labor-intensive assembly steps such as welding and stretching.

We can extrude complex shapes and geometries to give you a custom profile.

Materials

Also referred to as melt fluoropolymers as they are processed with traditional extrusion equipment, our line of fluoropolymer tubing is created through a proprietary compounding/blending process that provides custom color and radiopaque fillers while maintaining strict process control.

From pellet to product, Nordson MEDICAL processes an array of fluoropolymer materials including FEP, PFA, PCTFE, ETFE, PVDF, ECTFE, and EFEP. Nordson MEDICAL is one of the few companies in the world with expertise across all of these raw materials.

What are Fluoropolymers?

Fluoropolymers are chemically similar to polyolefins, with the exception of substituting fluorine for hydrogen. This drastically changes the properties. Fluorine's electronegativity causes the bond between carbon and fluorine to be the strongest bond in organic chemistry. This strong bond lends itself to fluoropolymers, achieving high temperature resistance, lubricity, electrical resistance, dielectric strength, and low reactivity.

All of these properties lend to fluoropolymers being extremely biocompatible, and thus ideal, for medical applications. Their drawback is in long-term-use applications under load, as fluoropolymers are notorious for cold-flow, or material creep.

- Fluoropolymer Tubing Options

- Single-lumen tubing

- Multi-lumen/profile extrusions

- Radiopaque tubing

- FEP heat shrink tubing

- Device Components

- Filled fluoropolymers

- Custom colors

- Radiopaque fill/stripe

- Etched liners

- Thin-wall/over-wire

- Tubing for packaging

- Filled fluoropolymers

- Value-Added Features

- OD etching

- Bondability to outer jacket

- Dip etching

- Ease of hub attachment

- Atraumatic taper and radius tips

- Flanging and flaring

- Ease of hub attachment

- Notching and drilling

- Welding

- Integration of radiopaque tip

- Visibility under x-ray or fluoroscopy imaging

- OD etching

Fluoropolymer Etching

Fluoropolymers are known for their combination of superior properties, whether chemical, electrical, or physical. Chances are that when you choose to use a fluoropolymer, it will have to be bonded with another part, whether metal, plastic, ceramic or composite, in order to perform its intended function. This can be a problem, since fluoropolymers are notorious for their lack of bondability. This lack of bondability is caused by the very stable, covalent carbon-fluorine bonds that make up your fluoropolymer. These bonds are so stable that the polymer has difficulty bonding to anything else, even temporarily. To improve bondability, one must remove some of these carbon-fluorine bonds. This process is called fluoropolymer etching, and is a solution that Nordson MEDICAL offers to combat the bondability problem.

Etching is a chemical process that removes the fluorine atoms from the surface layer of the fluoropolymer. This surface layer is so thin; it is most conveniently measured in Angstroms. Once the fluorine atoms are removed, the carbon atoms left behind in the etched polymer quickly form temporary bonds with atoms from the air, such as oxygen, nitrogen, and sometimes even hydrogen. Since these bonds are much weaker, the carbon atoms are still reactive, reducing the surface lubricity and allowing for a more bondable product. Because of the loss of carbon-fluorine bonds, once the surface of your fluoropolymer is etched, the properties of the etched area are changed. One will no longer have the lubricous and low energy surface that is expected from a fluoropolymer. Instead, one will have a wettable, bondable, frictional surface upon which to glue, mold, or print onto your product.

While there are a variety of methods available for fluoropolymer etching, Nordson MEDICAL exclusively uses a solution of Sodium Naphthalene for our in house etching processes. We offer alternate etching chemistries through subcontracts currently in place with outside etching companies.

Etching will only affect the chemistry of the surface with which it comes in contact. The properties of your fluoropolymer are kept intact not only underneath the etched surface, but on the entire remaining unetched surface as well, meaning that the etched product's bulk properties are unaffected by this process.

The results of the etching are not permanent, however. If left unused for long periods of time or stored incorrectly, the etched part regains its initial low bondability.

Nordson MEDICAL offers a variety of etching configurations:

- In-line surface (OD) etching during extrusion

- Dip-etching, which offers more control such that only specific surface areas are etched

- Inside (ID) tube etching

- Aggressive etching that Nordson MEDICAL subcontracts for alternate etch chemistries (please contact our engineering staff for additional information)

At Nordson MEDICAL, all of our fluoropolymer products are custom manufactured to meet our customers' needs. We can assist whether you have a current design or require our engineering support to design an etching solution for your application.

Nylon is a high-performance polyimide, and comes in two offerings, Nylon 11 and Nylon 12.

- Nylon 11: Flexible, lower density, bio-based engineering plastic derived from renewable resource, with excellent impact strength

- Nylon12: More rigid and higher density

Nylon 11 and 12 are great alternatives due to processability, mechanical strength and being a high-performance material, exuding the following properties:

- High Burst Pressure Resistance

- Great Chemical Resistance

- Biocompatibility and Sterilization Compatibility

- Processibility

Nylon is most typically used for balloon tubing applications due to its high burst pressure resistance and flexibility. Other common applications include:

- Catheter Shafts

- Drug Delivery

- Multilayer

Pebax: In the family of polyether block amide (PEBA), Pebax is available in different grades, ranging from softer to more rigid durometers, offering flexibility and resilience.

Pebax is a common material and often chosen for the following properties:

- Lightweight and flexible

- Chemical resistance and biocompatibility

- Low modulus and processability for complex and dynamic applications

Pebax Grades

| Grade | Flexiblilty | Key Features |

|---|---|---|

| Pebax 2533SA01MED | Very High | Very soft and flexible |

| Pebax 3533SA01MED | High | Balanced softness and strength |

| Pebax 4033SA01MED | Medium-High | Balanced flexibility and rigidity |

| Pebax 5533SA01MED | Medium | Higher rigidity |

| Pebax 633SA01MED | Medium-Low | High stiffness |

| Pebax 7033SA01MED | Low | Rigid, high mechanical strength |

| Pebax 7233SA01MED | Very Low | Very rigid, high mechanical strength |

Common Pebax Applications:

- Catheter Shaft: Pushability, flexibility

- Drug Delivery: Chemical resistance

With excellent strength and heat endurance, PEEK is one of the few polymers that can replace metal, even in high-temperature sterilization applications. PEEK is a solution to invest in due to its many high-performing mechanical properties. This versatile material allows designers to heat form, tip, taper, flare, or flange complex designs.

Highest Strength-to-Weight Ratio Tubing

Our customers choose PEEK tubing for its exceptional strength and lightweight properties, offering excellent pushability along with resistance against kinking and heat. Nordson MEDICAL's PEEK tubing offers:

- Excellent thermal stability

- Chemical resistance

- Impact resistance

- Electrical insulation

- Biocompatibility

- High-tensile strength

- Low flammability

PEEK Component Applications

Nordson MEDICAL produces PEEK tubing for multiple applications:

| Application | Featured Material Properties |

|---|---|

| Balloon tube | High burst strength |

| Bushing | Abrasion and heat-resistant properties |

| Cannulae | Pushability, high torque and kink resistance |

| Delivery catheter | Pushability and kink resistance |

| Inner tubing | High-tensile strength |

| Insulator tubing | Electrical and heat-insulation properties |

| Needle jacket | Abrasion and scratch-resistant properties |

| Outer sleeve | Abrasion and heat-resistant properties |

| Shaped needle | Pushability, lubricity and heat-resistance |

Technical Information

Single-Lumen Extruded Tubing Technical Information

| Single-Lumen | Single-Lumen Ultrathin Wall | Single-Lumen Microthin Wall | |

|---|---|---|---|

| OD Range | From 0.003" (0.076 mm) | 0.004"–0.120" (0.102 mm–3.048 mm) | 0.020"–1" (0.508 mm–25.4 mm) |

| OD Tolerance | From ± 0.0003" (± 0.008 mm) | From ± 0.0002" (± 0.005 mm) | From ± 0.0004" (± 0.001 mm) |

| Wall | From 0.001" (0.025 mm) | From 0.0005" (0.013 mm) | 0.00025"–0.003" (0.006 mm–0.08 mm) |

Length:

Standard: 62" (157 cm)

Custom Cutting:

- Maximum straight length: 96" (Longer lengths possible for some sizes)

- Minimum: 0.020" or less

Fluoropolymer Materials:

PTFE, FEP, ECTFE, EFEP, ETFE, PCTFE, PFA, PVDF

Typical Thermoplastic Materials (contact us for additional options):

ABS, Acetal, Arnitel, Bionate, Carbothane, Chronosil, EFEP, Elastollan, EVA, EVAL, HDPE, Hytrel, LDPE, LLDPE, Medalist, NEOFLONTM EFEP RP-5000, NEOFLONTM PFA AP-210, Nylon 11, Nylon 12, Nylon 6, Pebax® 35D, Pebax 45D, Pebax 55D, Pebax 63D, Pebax 70D, Pebax 72D, Pebax/EverGlide®, Pebax/Mobilize, Pebax/PEBASlide, Pebax/ProPell STM PEEK, Pellethane 55D, Pellethane 75D, PET, Polycarbonate, Polypropylene, Polysulfone, Primacor, PVC, Resin, Rezilient, Santoprene, SEBS, Tecoplast, Tecothane, Texin, Thermoplastic Polyimide

Printing:

Most can be printed using conventional techniques

Multi-Lumen Extruded Tubing Technical Information

| OD Range | 0.030" (0.8 mm) and up |

| OD Tolerance | From ± 0.001" (± 0.025 mm) |

| Lumen Diameter | 0.006" (0.152 mm) and up |

| Length | Standard: 62" (157 cm)

Custom Cutting

|

| Typical Materials (Contact us for additional options) | Polyurethane, Pebax, PET, Nylon, Polypropylene, PEEK, Polycarbonate, HDPE, TPE |

| Printing | Can be printed using conventional techniques |

Co-Extruded Multi-Layer Extruded Tubing Technical Information

Up to three discrete layers

| OD Range | From 0.016" (0.410 mm) |

| OD Tolerance | From ± 0.00027" (± 0.007 mm) |

| Wall | From 0.0016" (0.041 mm) |

| Length | Standard: 62" (157 cm)

Custom Cutting:

|

| Materials | Outer jacket:

Polyurethane, Pebax, PET, Nylon, Polypropylene, HDPE, TPE Inner jacket: Polypropylene, HDPE, Polyurethane |

| Printing | Can be printed using conventional techniques |

Co-Extruded/Stripe Extruded Tubing Technical Information

| OD Range | From 0.020" (0.508 mm) |

| OD Tolerance | From ± 0.00027" (± 0.007 mm) |

| Wall | From 0.0016" (0.04 mm) |

| Length | Standard: 62" (157 cm)

Custom Cutting:

|

| Typical Materials (Contact us for additional options) | Polyurethane, Pebax, Nylon, TPE

Stripes: a range of radiopaque fillers |

| Printing | Can be printed using conventional techniques |

General

| Property | ASTM | PTFE | FEP | PFA | ETFE | PVDF | PCTFE | ECTFE |

|---|---|---|---|---|---|---|---|---|

| Chemical/Solvent Resistance | D543 | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent |

| Density | D792 | 2.22 g/cc | 2.15 g/cc | 2.15 g/cc | 1.7-1.86 g/cc | 1.76-1.88 g/cc | 2.10-2.17 g/cc | 1.68 g/cc |

| Water Absorption | D570 | <0.01% | <0.01% | <0.03% | <0.03% | <0.06% | <0.02% | <0.01% |

| Refractive Index | — | 1.35 | 1.338 | 1.34 | 1.40 | 1.42 | 1.435 | 1.447 |

| Standard Percent Crystallinity | — | >90% | 70% | 48-70% | 50% | 35-70% | 30-70% | 50-55% |

Mechanical

| Property | ASTM | PTFE | FEP | PFA | ETFE | PVDF | PCTFE | ECTFE |

|---|---|---|---|---|---|---|---|---|

| Specific Gravity | D792 | 2.13-2.20 | 2.12-2.17 | 2.12-2.17 | 1.70-1.76 | 1.78 | 2.12 | 1.68 |

| Elongation | D638 | 200-550% | 325% | 300% | 300% | 50-400% | 100-250% | 200-300% |

| Tensile Strength | D638 | 20-35 MPa | 23 MPa | 24 MPa | 37-50 MPa | 17-48 MPa | 34-39 MPa | 30-48 MPa |

| Young's Modulus | D638 | 0.39-0.6 GPa | 0.44-0.64 GPa | 0.45 GPa | 0.49-0.78 GPa | 0.5-5 GPa | 1.4 GPa | 1.4-2.1 GPa |

| Flexural Modulus | D790 | 0.275-0.7 GPa | 0.58 GPa | 0.6-0.7 GPa | 0.7-1.2 GPa | 1.3-7 GPa | 1.2-1.4 GPa | 1.6-2 GPa |

| Hardness Durometer | — | 55 Shore D | 0.58 GPa | 55-60 Shore D | 63-75 Shore D | 65-82 Shore D | 80-90 Shore D | 70-90 Shore D |

| Coefficient of Friction | — | 0.02 (on steel) | 0.05 (on steel) | 0.2 (on steel) | 0.06 (on steel) | 0.15 (on steel) | 0.08 (on steel) | 0.19 (on steel) |

Thermal

| Property | ASTM | PTFE | FEP | PFA | ETFE | PVDF | PCTFE | ECTFE |

|---|---|---|---|---|---|---|---|---|

| Melting Point | — | 327°C | 260°C | 305°C | 267°C | 173°C | 212°C | 240°C |

| Glass Transition Temperature | — | 127°C | 80°C | 100°C | 40-80°C | -35°C | 120°C | 85°C |

| Upper Service Temperature | — | 260°C | 204°C | 260°C | 176°C | 150°C | 132°C | 150-170°C |

| Thermal Conductivity | — | 0.25 W/m-K | 0.19-0.25 W/m-K | 0.15-0.25 W/m-K | 0.24 W/m-K | 0.17-0.19 W/m-K | 0.84 W/m-K | 0.151-0.157 W/m-K |

| Linear Coefficient of Thermal Expansion | D696 | >11.6 10-5/°C | 8.3-10.5 10-5/°C | 13 10-5/°C | 13 10-5/°C | 6.6 10-5/°C | 7 10-5/°C | NA |

Electrical

| Property | ASTM | PTFE | FEP | PFA | ETFE | PVDF | PCTFE | ECTFE |

|---|---|---|---|---|---|---|---|---|

| Dielectric Constant | D150 | 2.1 MHz | 2.1 MHz | 2.1 MHz | 2.6 MHz | 8.5 MHz | 2.6 MHz | 2.55 MHz |

| Dielectric Strength | D149 | >1400 V/mil | >1400 V/mil | >1400 V/mil | 1600 V/mil | 1700 V/mil | 3000 V/mil | NA |

| Volume Resistivity | D257 | >1018 ohm-cm | >1018 ohm-cm | >1018 ohm-cm | >1016 ohm-cm | >1014 ohm-cm | >1017 ohm-cm | >1016 ohm-cm |

| Surface Resistivity | D257 | >1017 ohm/sq. | >1017 ohm/sq. | >1017 ohm/sq. | >1015 ohm/sq. | >1014 ohm/sq. | >1015 ohm/sq. | >1014 ohm/sq. |

| Linear Coefficient of Thermal Expansion | D696 | >11.6 10-5/°C | 8.3-10.5 10-5/°C | 13 10-5/°C | 13 10-5/°C | 6.6 10-5/°C | 7 10-5/°C | NA |

PTFE:

PTFE was the first fluoropolymer to be discovered. It is also the most difficult to process. Because its melt temperature is only a few degrees shy of its degradation temperature, it cannot be melt-processed. PTFE is processed using a sintering method, where the material is heated to a temperature below its melting point for an extended period of time. The PTFE crystals unravel and interlock with each other, allowing the plastic to take the shape it is intended to take. PTFE has been used in the medical industry as early as the 1960s. Today, it is typically used for split-sheath introducers and dilators, as well as lubricious catheter liners and heat shrink tubing. Because of the chemical stability and low coefficient of friction, PTFE is an ideal catheter liner.

FEP:

FEP is chemically very similar to PTFE. It adds on a CF3 pendant group every fourth carbon, which dramatically lowers its crystallinity. Because it is less crystalline than PTFE, its melt temperature is lower, which allows it to be melt-processed. All of its other material properties are nearly identical to those of PTFE. It is used for a variety of purposes where sterilization and heat resistance are the biggest factors. It can also be used to make high-temperature heat shrink tubing used for reflow catheter layups.

ECTFE:

ECTFE is a copolymer of PE and PCTFE. It is known for impact strength and good low temperature properties. For this reason, it is used as a gasket material for stored gases, particularly oxygen. It can also be used as a filtering material.

EFEP:

EFEP is a copolymer of FEP and polyethylene. This fluoropolymer is special because it can bond with other materials without requiring an etching step, yet it still retains the chemical resistance that is the trademark of fluoropolymers. It is also more optically clear than other fluoropolymers.

ETFE:

ETFE is a copolymer of PTFE and polyethylene. This allows the polymer to take on some of the properties of both individual plastics. It is also very resistant to UV light. It is used for medical applications that involve exposure to UV light on a regular basis. It is often considered a high strength version of FEP or PFA.

PCTFE:

PCTFE is known primarily for its low water vapor transmission rate. Because of this, it is often used in packaging of things that are extremely moisture-sensitive. It is also used for chemical-resistant barriers and coatings. The addition of the chlorine atom into its structure dramatically lowers its melting temperature due to chlorine's bulkiness.

PFA:

Perfluoroalkoxy (PFA) is the melt-processable fluoropolymer with the highest temperature resistance. It is often compared with FEP, which it surpasses in fatigue life, but falls short in moisture resistance. Its advantage in medical applications is that it is similar to PTFE in fatigue life but can be manufactured in more complex ways as it is melt-processable.

PVDF:

Polyvinylidene fluoride (PVDF) is used when chemical purity is a must. It also demonstrates piezoelectric behavior, which is a contraction or expansion in response to a magnetic field. It is a popular material used to create tools used for protein separation.

Melt Fluoropolymers Specifications

| Material | Features | Capabilities | Configurations | Fillers | Sterilization | Enhancements |

|---|---|---|---|---|---|---|

| Fluorinated Ethylene

Propylene (FEP) |

Chemical Resistance

Melt-Processable Good Dielectric Properties Good Surface Lubricity |

OD up to 0.4"

Wall Down to .0015" 2-10 Lumens Custom Heat Shrink Sizes |

Beading/Custom Profiles

Multi-Lumen Heat Shrink |

Bismuth Trioxide

Barium Sulfate Titanium Dioxide Tungsten Custom Colors |

EtO

Steam/Autoclave |

Notching/Drilling

Flaring/Flanging/Tipping Etching |

| Ethylene

Tetrafluoroethylene (ETFE) |

Chemical Resistance

Melt-Processable Good Dielectric Properties Aging-Resistant |

OD up to 0.4"

Wall Down to .0015" 2-10 Lumens |

Beading/Custom Profiles

Multi-Lumen |

Bismuth Trioxide

Barium Sulfate Titanium Dioxide Tungsten Custom Colors |

EtO

Steam/Autoclave Gamma E-Beam |

Notching/Drilling

Flaring/Flanging/Tipping Etching |

| Ethylene Fluorinated

Thylene Propylene (EFEP) |

Chemical Resistance

Adherence to Polymers Without Etching Very High Transparency |

OD up to 0.4"

Wall Down to .0015" 2-10 Lumens |

Beading/Custom Profiles

Multi-Lumen |

Bismuth Trioxide

Barium Sulfate Titanium Dioxide Tungsten Custom Colors |

EtO

Gamma |

Notching/Drilling

Flaring/Flanging/Tipping |

| Perfluoroalkoxy

(PFA) |

Chemical Resistance

Melt-Processable High Purity Good Stiffness |

OD up to 0.4"

Wall Down to .0015" 2-10 Lumens |

Beading/Custom Profiles

Multi-Lumen |

Bismuth Trioxide

Barium Sulfate Titanium Dioxide Tungsten Custom Colors |

EtO

Steam/Autoclave |

Notching/Drilling

Flaring/Flanging/Tipping Etching |

| Polyvinylidene

Fluoride (PVDF) |

Chemical Resistance

Easily Melt-Processable High Purity |

OD up to 0.4"

Wall Down to .0015" 2-10 Lumens |

Beading/Custom Profiles

Multi-Lumen |

Bismuth Trioxide

Barium Sulfate Titanium Dioxide Tungsten Custom Colors |

EtO

Steam/Autoclave Gamma E-Beam |

Notching/Drilling

Flaring/Flanging/Tipping Etching |

| Polychlorotrifluoroethylene

(PCTFE) |

Chemical Resistance

Good Temp Resistance Melt-Processable Excellent Stiffness |

OD up to 0.4"

Wall Down to .0015" 2-10 Lumens |

Beading/Custom Profiles

Multi-Lumen |

Bismuth Trioxide

Barium Sulfate Titanium Dioxide Tungsten Custom Colors |

EtO

Steam/Autoclave Gamma E-Beam |

Notching/Drilling

Flaring/Flanging/Tipping Etching |

| Ethylene

Chlorotrifluoroethylene (ECTFE) |

Chemical Resistance

Melt-Processable Good Dielectric Properties Good Surface Lubricity |

OD up to 0.4"

Wall Down to .0015" 2-10 Lumens |

Beading/Custom Profiles

Multi-Lumen |

Bismuth Trioxide

Barium Sulfate Titanium Dioxide Tungsten Custom Colors |

EtO

Steam/Autoclave |

Notching/Drilling

Flaring/Flanging/Tipping Etching |

Contact us for PEEK tubing specifications.

Contact Us »Tapered and Bump Extruded Tubing Specifications

Available in single- or multi-layer coextruded configurations. Tapered wall thickness with constant ID available.

| OD Range | From 0.02" (0.5 mm) |

| OD Tolerance | From ± 0.0003" (± 0.008 mm) |

| Wall Transition | From 0.001" (0.025 mm) over discrete transition |

| Length | Standard: 62" (157 cm)

Custom Cutting:

|

| Typical Materials (contact us for aditional options) | Polyurethane, Nylon, Pebax, Polyethylene, TPE |

| Printing | Can be printed using conventional techniques |

Profile Extruded Tubing Specifications

Can be designed in various shapes (e.g., crescent, H-shape, rod)

| OD Range | 0.010"–0.14" (0.254 mm–3.56 mm) |

| OD Tolerance | ± 0.0003" (± 0.007 mm) |

| Wall | N/A |

| Length | Standard: 62" (157 cm)

Custom Cutting:

|

| Fluoropolymer Materials | PTFE, FEP, ECTFE, EFEP, ETFE, PCTFE, PFA, PVDF |

| Typical Thermoplastic Materials (contact us for additional options) | Polyurethane, Pebax, PET, Nylon, Acetal, HDPE, Polypropylene |

| Printing | Can be printed using conventional techniques |

Tipping

| Materials | Capabilities | Dimensions | Tolerances | Performance Characteristics | Some Clinical Applications |

|---|---|---|---|---|---|

| All thermoplastic polymers can

be formed, including: LDPE HDPE Polyethylene(PE) copolymers Polypropylene (PP) Polyurethans (PU) & PU blends Pebax® PEEK Tungsten-loaded | Closed tips

Tapered tips Radiused tips Angled tips Soft tips Radiopaque tips Neck Down Butt welds Overlap welds Flaring Bulbous tips Polyimide reinforced Constant IDs Tapered IDs Flashless Deflashed |

Dimensions from 2 Fr - 45 Fr

Taper lengths from 0.039" (1 mm) - 3.543" (90 mm) |

Tip OD tolerances ±0.0002" (0.005 mm) General tolerances ± 0.001" (0.025 mm) |

High temperature tipping

Process controls Fast cycle times 1-, 2-, & 4-up tipping Validatable processes |

Aneurysmembolization

Urinary Angiographic Central venous catheters CVC IV tips Dilator tips Coronary Contraceptive devices - IUCD And more |

Printing

| Materials | Capabilities | Dimensions | Tolerances | Performance Characteristics | Some Clinical Applications |

|---|---|---|---|---|---|

| Pre-treated polyethylene (PE)

Pre-treated polypropylene (PP) Polyurethane (PU) Polyamide (PA) Polystyrene (PS) ABS Polycarbonate (PC) Rigid & soft PVC Coated substrates Thermoset plastics |

Text

Numeric Depth marks Corona surface treatment Plasma surface treatment Medical-grade TPU, TPR, & PP solvent-based inks Range of colors available |

360° marking

Taper lengths from 0.039" Single-plane printing Adjustability for various tube diameters Print areas up to 33.465" (850 mm) |

Position tolerances

up to 0.02" (0.500 mm) |

High temperature Tipping

Y- & Z-axis servo drives Y-axis servo control allows the pad to pick up various artworks from a single cliche Adjustable vacuum control Automatic pad cleaning |

Angiographic catheters

Balloon catheters Contraceptive devices - IUCD Central venous catheters Dilators Tracheal devices Urinary devices And more |

Hole Forming

| Materials | Capabilities | Dimensions | Tolerances | Performance Characteristics | Some Clinical Applications |

|---|---|---|---|---|---|

| Teflon® PTFE

Teflon® FAP Silicone Polyimide Pebax® PEEK Polyurethane (PU) PVC (vinyl) Latex & natural rubber TPE PET Polycarbonate (PC) Acrylic Polyethylene (PE) Nylon 6 & small diameter nylon 12 Delrin® (acetal) Polypropylene (PP) |

Any hole or skive pattern

is achievable |

Holes as small as 0.009" (0.229 mm)

Razor-sharp cutting edges Drill edge diameters sharpened to ±0.0007" (0.018 mm) |

Multi-lumen configurations

from 2 - 8+ lumens |

Drill tip registration

Hole plug detection Precise location & performation of individual lumens Long drill life Collet-style drill head for punches & ejector pins Three cutting tip profiles: outside, middle, & inside |

Aneurysm embolization

Contraceptive devices - IUCD Drainage catheters And more |

Over-Molding

| Materials | Capabilities | Dimensions | Tolerances | Performance Characteristics | Some Clinical Applications |

|---|---|---|---|---|---|

| Wide variety of thermoplastic polymers

Substrate Materials

|

Over-molding

Insert molding Y-connectors & hubs Strain reliefs Luers, connectors, & hubs Other assemblies Incorporated into handles Profiles, size, & performance are limitless |

All projects assessed separately based on

material selection, quantity, and size |

General tolerances ±.002" (0.051 mm)

- ±.003" (0.076 mm) |

Increased product value

Additional functionality Reduced post processing & assembly Repeatable & validatable Single cavity & up to 4 or 8 cavities Cold or hot runners |

Common catheter shafts - luers, connectors, hubs

Strain reliefs Handles Endoflator devices And more |