Peelable Polyester Heat Shrink Tubing

Request a Quote »

PolyPeel™ Peelable Polyester Heat Shrink Tubing

Experience the world’s thinnest, smallest, and strongest heat shrink tubing—now with easy removal.

Developed specifically for the medical device industry, our patent-pending peelable polyester heat shrink tubing delivers all the same benefits of the product you already know and trust—plus the added advantage of easy removal.

Request a Quote »

Easy-to-Remove Heat Shrink

Explore key features for reflow processing and catheter masking

- Provides a PFAS-free alternative for reflow processing, catheter masking and in-process wrapping/bundling

- Combines low temperature, high strength, and ultra-thin walls for unique processing applications

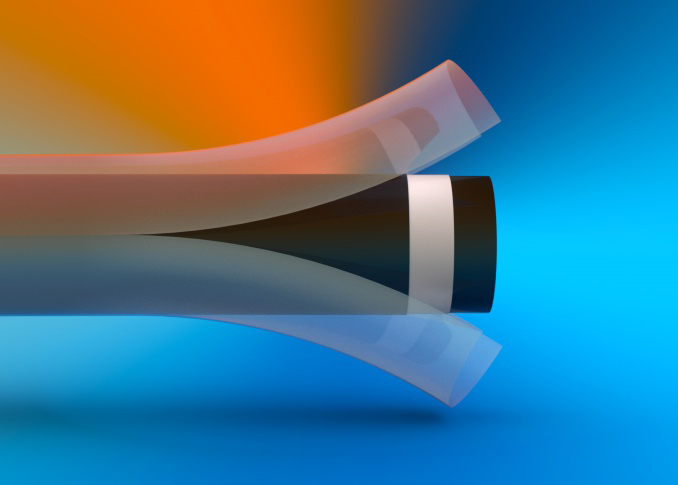

- Masks catheter sections for seamless, discrete coating applications

- Supports mid-process device containment, such as stent crimping

- Enables easy removal and reduced scrap caused by skivving substrate flaws

- Preserves profiles of packaged or in-process delivery systems, balloons, and implants

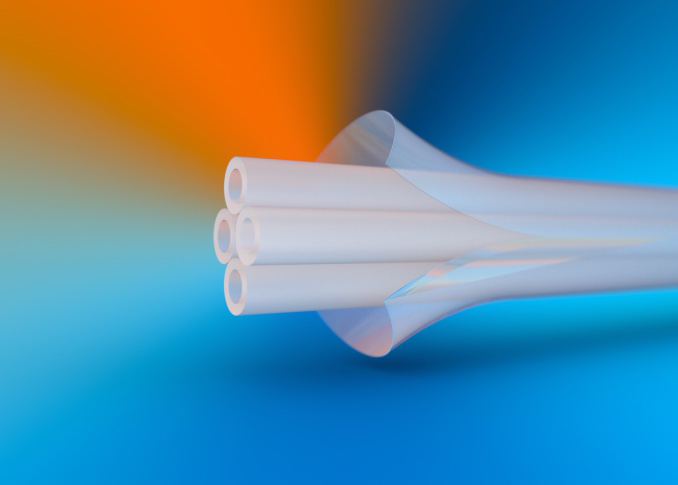

- Maintains tight-tolerance bundling of multiple devices for sleeve insertions

Why Peelable Polyester Heat Shrink?

A PFAS-Free Alternative for Manufacturing Aid Applications

- 100% PFAS-free material

- Thin walls for masking and bundling – as thin as 0.00025”

- Low shrink (or recovery) temperature to avoid damaging the substrate upon which it is shrinking – as low as 85ºC or 185ºF

- Tight ID tolerances – as tight as +/-0.001”

Applications of Peelable Polyester Heat Shrink Tubing

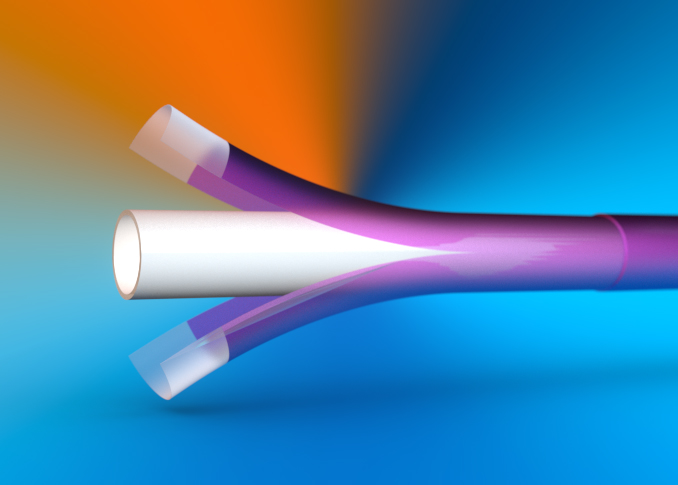

Although reflow is the most common application of heat shrink as a manufacturing aid, our customers use heat shrink in a variety of other sacrificial applications, including:

Applying a coating to a portion of a catheter while leaving other sections uncoated

Temporarily combining multiple catheters tightly together, enabling insertion into an outer carrier

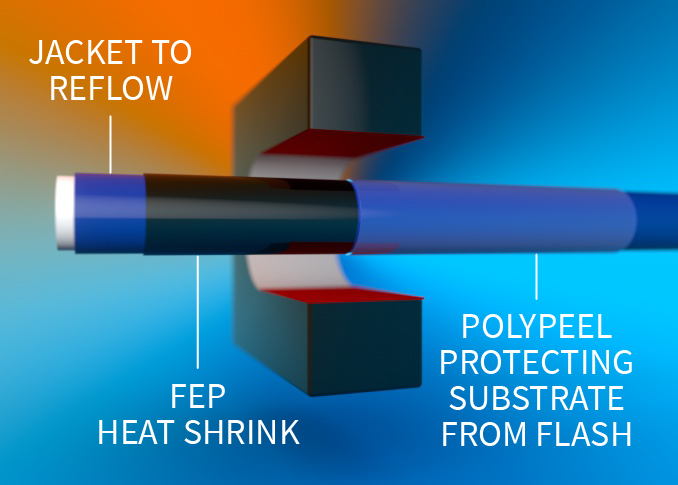

Preserving the wrapped profile or overall integrity of finished devices, preventing flash to catheter sections not being reflowed

Technical Information

Technical Information

| Inner Diameter | 0.080"–0.300" depends on wall thickness (typical standard tolerance ± 5%)

Custom sizes may be available upon request |

| Wall Thickness | 0.00025"–0.00050" (typical standard tolerance ± 0.0001")

0.0006"- 0.0010" (typical standard tolerance ± 20%) |

| Length | Standard: 50" (127 cm) minimum

Custom cutting lengths may be available upon request |

| Colors |

|

| Temperature Range | Start melting: 240°C ± 2°C, Melting point: 254°C ± 2°C |

| Shrinkage/Sizing |

|

| Electrical Properties |

Dielectric strength: >3,400 V/mil

Dielectric constant: 2.7 Dissipation factor: 0.075 Volume resistivity: 5.4 x 1015 ohm-cm Surface resistivity: 1.6 x 1015 Ohm/square |

| Sterilization |

|

| Biocompatibility | Biocompatible (ISO 10993) |

| Printing | Can be printed using conventional techniques |

| Per- and Polyfluoroalkyl Substances (PFAS) Content | PolyPeel™ is manufactured without the use of PFAS materials |

See the PET (Polyethylene Terephthalate) heat shrink tubing (PHST) specification standard requirements.

FEP Heat Shrink Tubing

Nordson MEDICAL's FEP heat shrink tubing is a high-performance material specifically designed for demanding catheter reflow medical device applications. Its exceptional heat and chemical resistance make it ideal for various manufacturing processes, including autoclaving and cleaning. The chemical structure of FEP allows for easier processing while maintaining its superior properties, ensuring durability, reliability, and compliance with medical device standards.