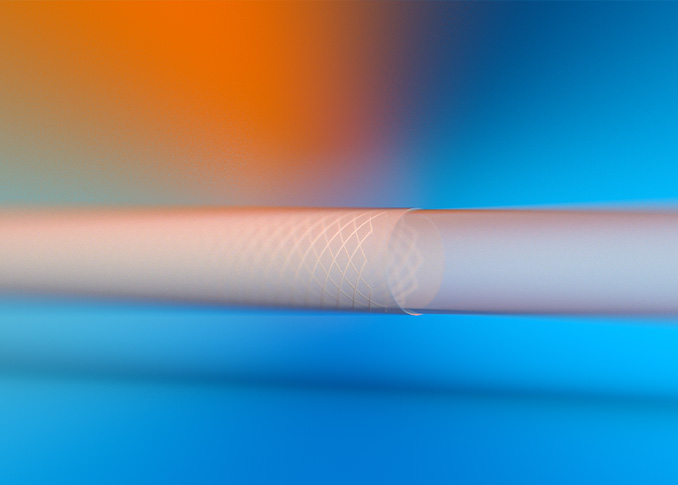

PET Heat Shrink Tubing

Shop Now »

PET Makes it Possible

Work With an Industry Leader

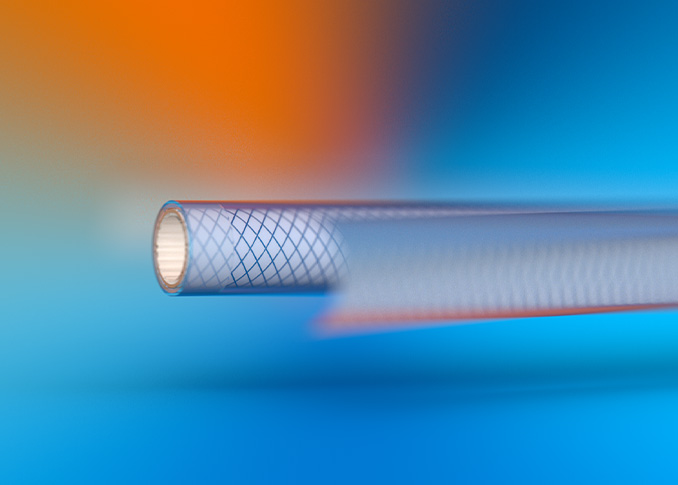

Nordson MEDICAL is known for having PET heat shrink tubing with the thinnest walls and strongest performance. Heat shrink tubing provides insulation, protection, stiffness, sealing, and strain reliefs for a variety of applications, without significantly adding to the profile of a device. A versatile alternative to conventional techniques, heat shrink is easy to use and quickly takes the shape of the object it's being applied to.

Nordson MEDICAL offers a range of in-stock heat shrink tubing sizes, colors, and printing, with custom solutions available to meet your specifications.

Shop Now »PolyPeel™ Peelable Polyester Heat Shrink Tubing

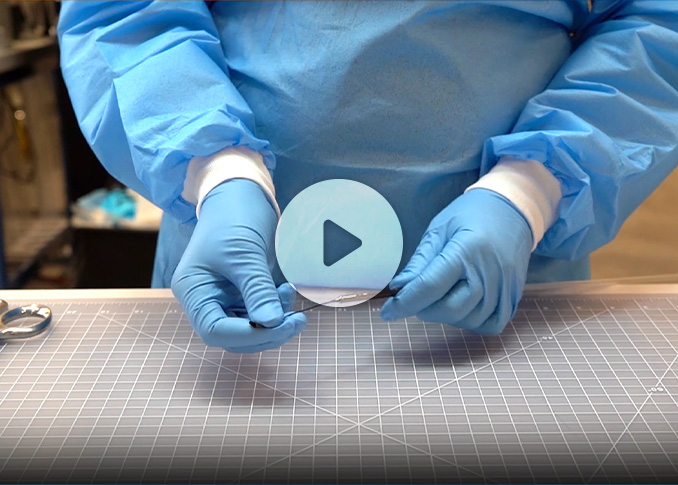

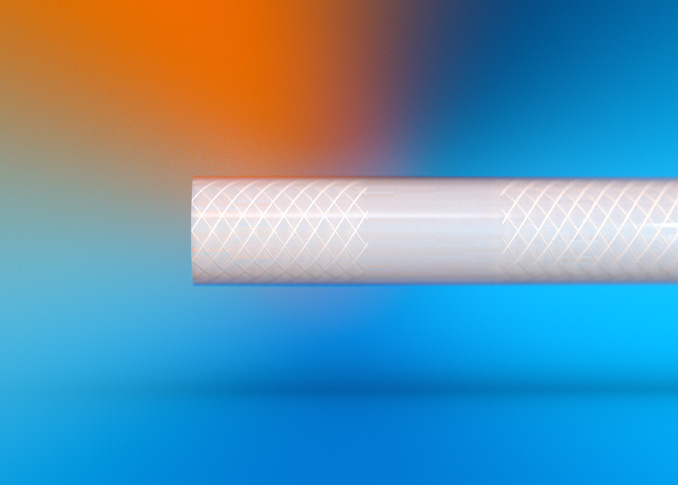

Nordson MEDICAL's polyester (PET) heat shrink tubing is ultra-thin-walled, high-strength, and available in optically clear or pigmented options. Developed specifically for the medical device industry, it has been at the forefront of medical device tubing innovation since its creation. Now, with our new patent-pending peelable polyester heat shrink tubing technology, you get all the same benefits of the product you already know and trust—plus the added advantage of easy removal. Simply make 1/4" incisions on one end of the tubing to achieve excellent peelability from one end to the other.

Thinnest Yet Strongest

Best-In-Class PET Heat Shrink Tubing

Polyethylene terephthalate (PET) medical heat shrink tubing combines incredible strength and durability with extraordinarily thin walls, and can be drawn-down while maintaining its strength. PET heat shrink can easily be left on a finished device without significantly affecting the profile. Its incredible dielectric strength makes PET heat shrink ideal for electrical insulation.

We are the exclusive supplier of medical PET heat shrink tubing, which uses a proprietary process developed by Vention Medical / Advanced Polymers.

Stock Options

Speed Time to Market

Our online store offers a full range of thin-wall heat shrink tubing products.

- Inner diameter (ID) range: 0.006"–0.5"

- Wall thickness: as thin as 0.0001"

PET Heat Shrink Tubing Instructional Video Library

Make the Most of Our Product

PET Reflow Heat Shrink Tubing

Engineered for high-efficiency reflow processing with broad material compatibility, this PET Reflow heat shrink line offers a PFAS-free option with equivalent peel strength. Supporting faster reflow speeds to help increase throughput and reduce manufacturing costs, you now have expanded choices alongside traditional FEP solutions.

Applications of PET Heat Shrink Tubing

PET heat shrink tubing is used for a wide range of medical device applications and as a manufacturing aid.

Because of the high dielectric strength of PET, it is ideal for use with energy-generating or sensing devices and can be left on devices with negligible effect on profile.

Because of its ultrathin walls and high strength, our PET heat shrink tubing can add stiffness to some or all of a shaft while adding very little to the profile.

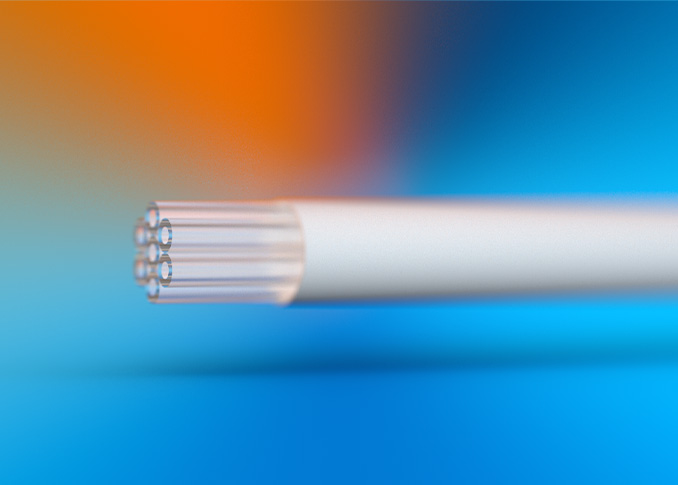

The high hoop strength and perforation resistance of our PET heat shrink tubing can encapsulate and collapse braid terminations, preventing end-wire exposure while preserving low profile.

Our custom configurations allow for pad printing or marking the tubing to avoid printing directly on a device.

PET heat shrink tubing can cover parts that require a thin but very strong outer layer, or bundle and compress components together into a tight configuration.

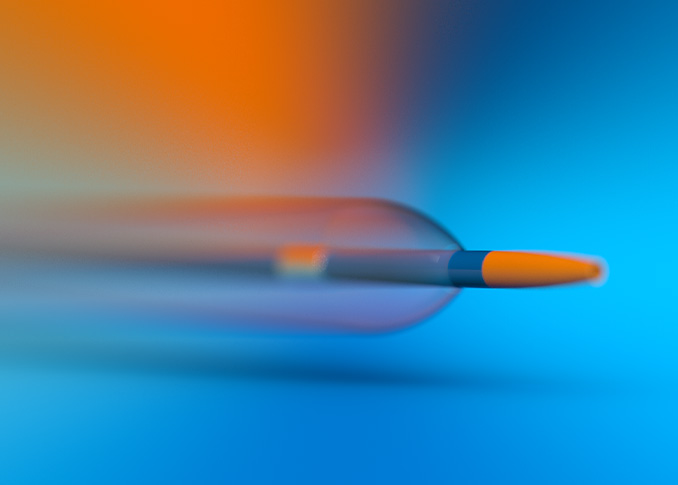

PET heat shrink tubing can bond both ends of a balloon to a catheter or add strength to an existing bond.

Thin-walled PET heat shrink tubing can be applied to sections of a catheter where coatings of various types are unwanted.

Using PET heat shrink tubing as an aid that is removed in process can be used for bundling, preserving the wrapped profile of a balloon or stent, masking, or preventing the need to scrap the entire catheter.

Read Our Ultrathin-Wall PET White Paper » Read Our PET Heat Shrink for Reflow Applications White Paper »

FEP Heat Shrink Tubing

Nordson MEDICAL's FEP heat shrink tubing is a high-performance material specifically designed for demanding catheter reflow medical device applications. Its exceptional heat and chemical resistance make it ideal for various manufacturing processes, including autoclaving and cleaning. The chemical structure of FEP allows for easier processing while maintaining its superior properties, ensuring durability, reliability, and compliance with medical device standards.

Technical Information

Technical Information

| Inner Diameter | 0.006"–0.020" (standard tolerance ± 0.001", typical)

0.021"–0.5" (standard tolerance ± 5%, typical) |

| Wall Thickness | 0.0001"–0.0005" (standard tolerance ± 0.0001", typical)

0.0006"–0.004" (standard tolerance ± 20%, typical) |

| Length | Standard: 50" (127 cm) minimum

Custom cutting:

|

| Colors |

|

| Temperature Range | Long-term use (cryogenic):

-196°C (-320.8°F)–135°C (275°F) Short-term use: Up to 200°C (392°F) Melting point: 235°C (455°F) |

| Shrinkage/Sizing |

|

| Electrical Properties | Polyethylene terephthalate (PET) has one of the highest dielectric strengths of any thermoplastic material

Dielectric strength: >4,000 V/mil Dielectric constant: 3.3 Dissipation factor: 0.0025 Volume resistivity: 1018 ohm-cm Surface resistivity: 1014 Ohm/square |

| Sterilization |

|

| Biocompatibility | Biocompatible (ISO 10993) |

| Printing | Can be printed using conventional techniques |

The ability to "draw down" PET heat shrink tubing allows you to reduce tube diameter by up to 70% while maintaining a high-strength, thin-wall heat shrink tube.

- PET heat shrink tubing ratios are different from those of other tubing:

- Tight fit is best: 15% gap or less

- PET should be sized no larger than 15% above the maximum diameter of your part

- Target ratio is 1.1:1

- Shrinking temperature:

- Approximately 70°C (158°F)–190°C (374°F)

- Typical shrinking temperature recommended for most applications: 150°C (302°F)

See the PET (Polyethylene Terephthalate) heat shrink tubing (PHST) specification standard requirements.