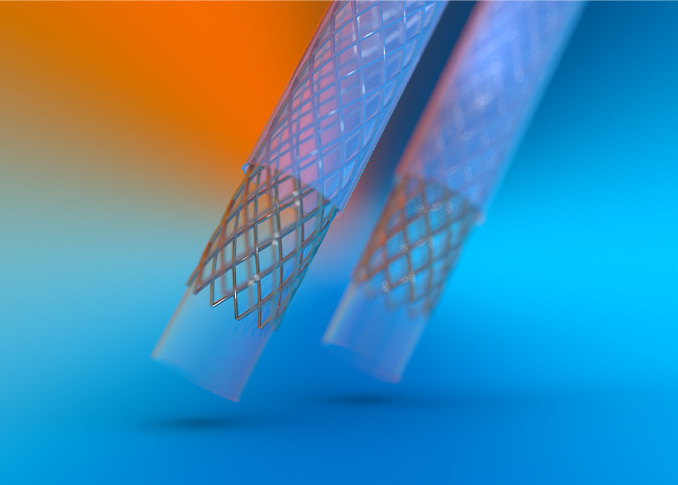

FEP Heat Shrink Tubing

Shop Now »

FEP Heat Shrink Tubing

For Demanding Catheter Reflow Applications

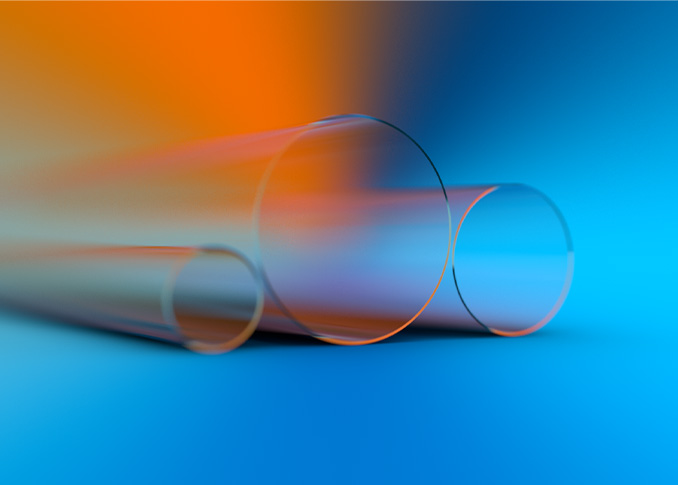

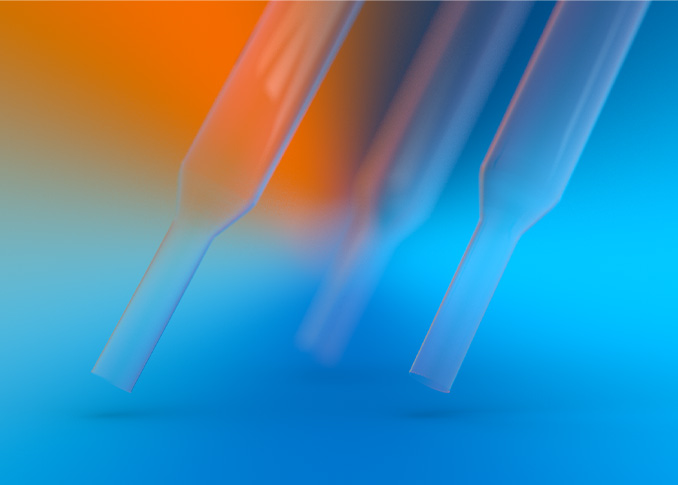

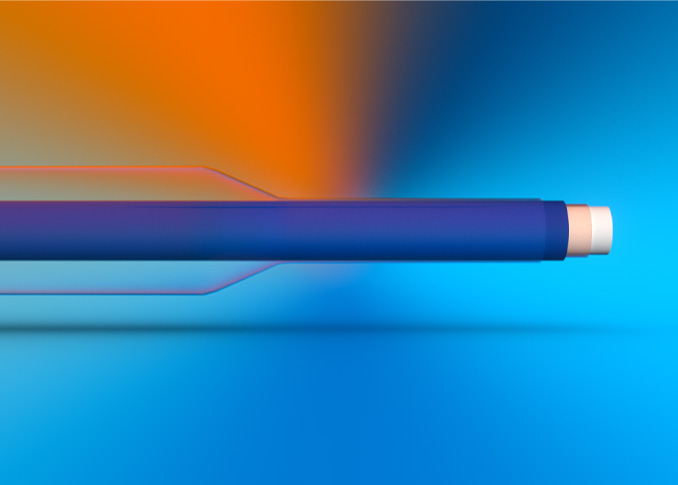

Nordson MEDICAL's FEP heat shrink tubing is a high-performance material specifically designed for demanding catheter reflow medical device applications. Its exceptional heat and chemical resistance make it ideal for various manufacturing processes, including autoclaving and cleaning. The chemical structure of FEP allows for easier processing while maintaining its superior properties, ensuring durability, reliability, and compliance with medical device standards.

Shop FEP Heat Shrink Tubing

Available in Our Web Store

Nordson MEDICAL's high-quality FEP heat shrink tubing is now available in our online store, with expedited lead times. To better serve you, we've expanded our production capabilities and are offering one-week lead times on all FEP heat shrink tubing web orders.

Need something custom? Contact us, and our team of experts will help you find the perfect solution for your appliaction.

Shop Now »

Features and Benefits

FEP Heat Shrink Tubing

Nordson MEDICAL engineers around optimal functionality. Our FEP heat shrink tubing is tailored to your exact requirements. Features and benefits of our FEP heat shrink tubing include:

- Heat-resistance up to 450°F, ensuring durability and minimizing the need for frequent replacements

- Enhanced surface lubricity and anti-adhesive properties to ensure effortless installation, facilitate easy removal, and extend component lifespan without contamination

- Silicone-free manufacturing process to avoid cross-contamination and improve product quality

- Customizable sizes to tailor our solutions to your needs

- Exceptional transparency for clear visability of medical components and unobstructed light transmission during procedures

- Low longitudinal shrinkage to avoid the need to constrain the ends

Tailored to Your Exact Needs

Stock and Custom Options

- Maximum expanded ID: 0.400"

- Recovered ID limits: 0.020"-0.300"

- Recovered wall thickness: 0.0025"-0.015"

- Upper service temperature: 399°F (204°C)

- Shrink temperature: 410°F (210°C)

- Custom shrink ratios up to 1.8:1

- Longitudinal shrinkage: typically <5%

- Length of tubing: 36"-82"

- Custom lengths below 36" upon request

- Melt recovery temperature: 425°F (218°C)

- Melting point: 500°F (260°C)

Technical Information

FEP Heat Shrink Tubing General Specifications

| Chemical/Solvent Resistance | Excellent |

| Density | 2.15 g/cc |

| Water Absorption | <0.03% | Refractive Index | 1.338 |

| Standard Percent Crystallinity | 70% |

FEP Heat Shrink Tubing Mechanical Specifications

| Specific Gravity | 2.12-2.17 |

| Elongation | 325% |

| Tensile Strength | 23 MPa |

| Young's Modulus | 0.44-0.64 GPa |

| Flexural Modulus | 0.58 GPa |

| Hardness Durometer | 55 Shore D |

| Coefficient of Friction | 0.05 (On Steel) |

FEP Heat Shrink Tubing Thermal Specifications

| Melting Point | 260°C |

| Glass Transition Temperature | 80°C |

| Upper Service Temperature | 204°C |

| Thermal Conductivity | 0.19-0.25 W/m-K |

| Linear Coefficient of Thermal Expansion | 8.3-10.5 10-5 °C |

FEP Heat Shrink Tubing Electrical Specifications

| Dielectric Constant | 2.1 MHz |

| Dielectric Strength | >1400 V/mil |

| Volume Resistivity | >1018 ohm-cm |

| Surface Resistivity | >1017 ohm/sq |

FEP Heat Shrink Tubing Features

| Material | Fluorinated Ethylene Propylene (FEP) |

| Features | Chemical Resistance Melt-Processable Good Dielectric Properties Good Surface Lubricity |

| Capabilities | Max Recovered IDs from 0.020" to 0.300" Wall Down to 0.0025" Custom Heat Shrink Sizes Shrink Ratios Up to 1.8:1" Custom Colors |

| Sterilization | EtO |

| Enhancements | Etching Slitting |