Cannulae - Polymer Solution Casting

Request a Quote »

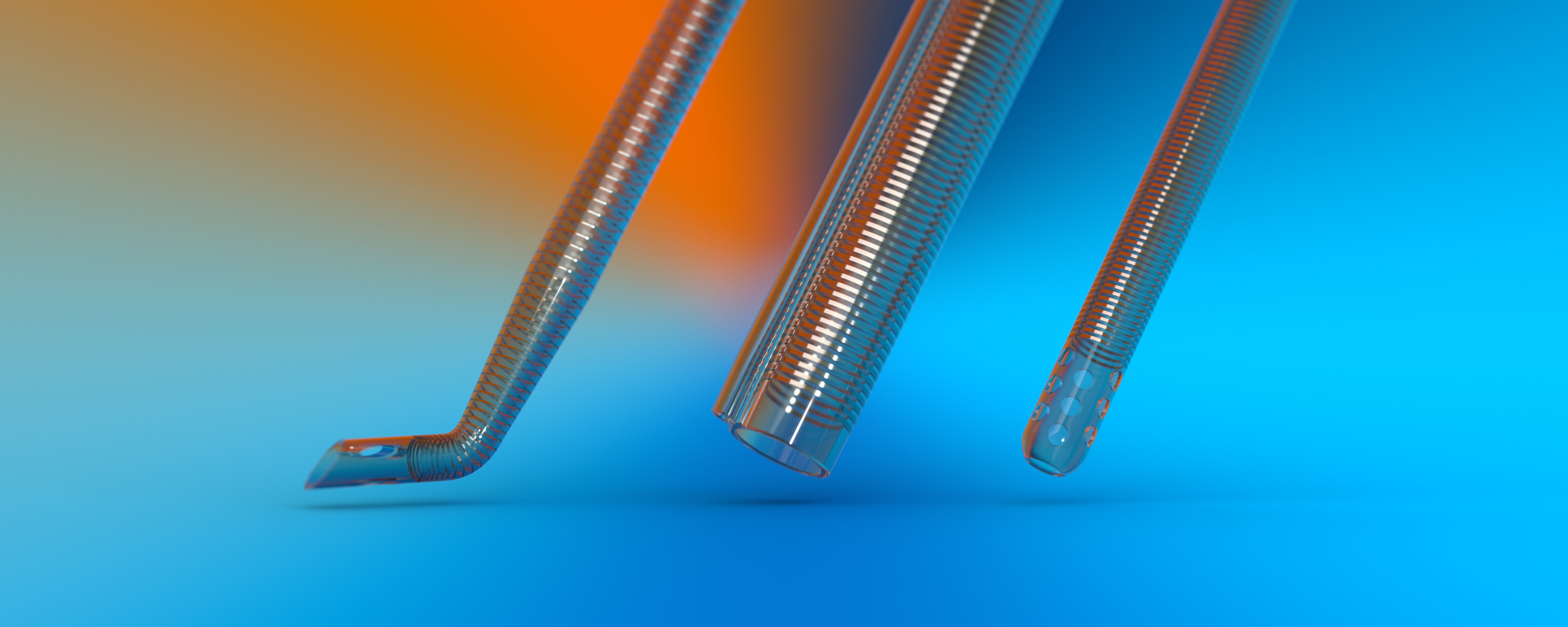

Cannulae

Polymer Solution Casting

Nordson MEDICAL is the world's leading contract manufacturer of cardiopulmonary vascular cannulae, catheters, and specialized medical tubing for a wide range of clinical applications. The key is our Avalon Laboratories polymer solution casting technology, which allows us to design and manufacture custom tubing with features not achievable by conventional extrusion or injection molding, at less cost.

Pebax® Coatings

Nordson MEDICAL has a new manufacturing approach to put Pebax® coatings on catheters and finished devices. Thinking beyond the typical manufacturing processes used in the market today, this method allows for seamless tapers along the full length of a catheter and offers unmatched flexibility with the elimination of fuse or glue joints. This new method can enable design options, previously thought to be impossible, to become a reality.

Applications

Of Polymer Solution Cast Cannulae

Polymer solution cast cannulae and catheters are used in a wide range of applications that require specialized medical tubing, including:

- Bariatrics/Obesity:

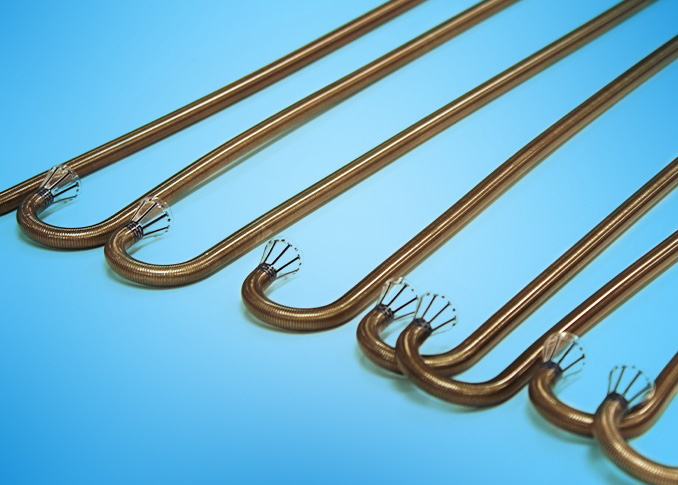

Some cannula have been used for gastrointestinal access, suction or delivery of obesity therapies. - Extracorporeal Life Support:

Most of our cannula are used to aid in life support by transporting blood in and out of the body to oxygenate or remove carbon dioxide during various surgical procedures (some listed below) where the heart or the lungs cannot perform these functions. Cannula may also support patients in recovery after their procedures or on a longer-term life assist basis.- Bypass surgeries

- Heart or lung support

- Ventricular assist device (VAD) therapies

- Peripheral Vascular Access/Stent Delivery:

Utilizing polymer solution casting technology, we have helped catheter designers to develop components in larger assemblies for access and stent delivery.

Many Properties; One Device

Enhanced Performance

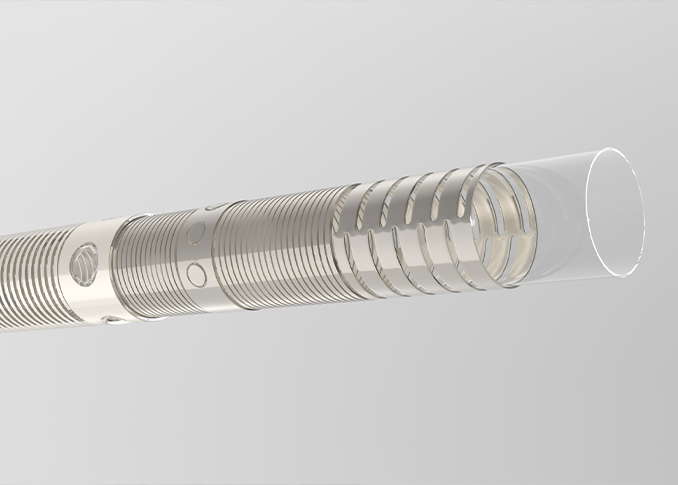

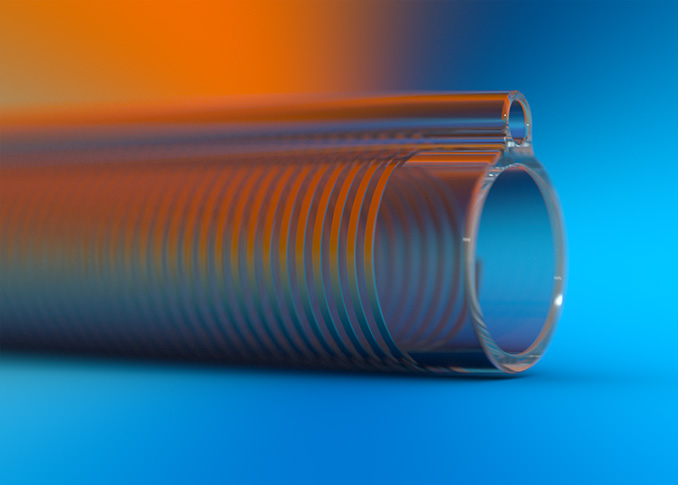

Applying liquid polymers in layers allows us to combine into one device materials with different properties including strength, lubricity, and flexibility. This technique allows varying wall thicknesses and diameters along the length of the device in a single-piece construction, while maintaining tight tolerances. We can also add reinforcement for flexibility, kink resistance, and maneuverability. Polymer solution casting results in thin walls, high flow, and superior column strength for enhanced performance.

Extensive Custom Capabilities

Of Our Polymer Solution Casting

- Single- or multilumen tubing

- Coaxial tubing

- Complex geometric designs

- Tapered designs

- Bump tubing

- Bending/shaping/forming

- Wide range of diameters and durometers

- Embedded reinforcement options

More About Polymer Solution Cast Products

Nordson MEDICAL produces a wide range of products for surgical and minimally invasive procedures, including valve replacement and repair, bypass surgeries, urology, lung support, and ventricular assist device (VAD) therapies, and other specialized medical tubing applications.

Technical Information

Polymer solution casting can help you achieve the performance you need. With our unique ability to combine several properties into a single-piece construction, and to create multiple lumens with tapers and other embedded features without bonds, you don't have to sacrifice design features. Our process can achieve things that traditional catheter manufacturing cannot.

Compare Our Construction

| Polymer Solution Casting | Tri-layer Solutions | |

|---|---|---|

| Target Applications | High Complexity

High Mix/Low Volume |

Moderate Complexity

Low Mix/High Volume |

| Up-Front Cost | Minimal | Higher |

| Scalability | Scale as needed | Limited access to low volume runs for custom extrusion |

| Construction | Single piece

No bond or butt joints No delamination |

Inner layer, tie layer. Requires bonding between layers

Material variation along length requires butt joints or stepped diameter |

| Strengths | Changes in diameter, wall thickness or material properties along the length

Smooth, continuous diameter transitions Embedded component variety |

Long lengths of identical, concentric tubing walls

Long lengths of identical, die-cut multi-lumen profiles Lower cost for volume runs |

| Challenges | Wall uniformity (thin layers conform to the geometry of embedded components)

Discrete process |

Tapered diameters

Changes in wall thickness along the length Smooth changes in material properties along the length Embedding complex features Ultra-thin layers |